A Perth based company servicing the local market with a range of packaging equipment and consumables. Stacks Image 1 We offer support for all of the equipment we supply with a friendly knowledgeable team of service engineers and have equipment

Allure-Pac provides face to face consultation to find the best solution for your situation. For service, supplies and spares, you can be certain that Allure-Pac will be available in person or over the phone to provide support.

Allure-Pac has been the trusted installer, supplier and support for packaging and labelling systems across Perth for years. We've installed and supported systems in different industries and environments.

Case Sealers are designed to fulfill your production requirements. Our systems work with both uniform and random sized cases. For years, we have been providing solutions for a variety of industries, including food & beverage and healthcare. We understand that there is not a one size fits all, which is why we will work with you to create the perfect sealing solution. Choose from operator required semi-automatic or no operator needed fully automatic models.

Flexicode is the ideal marking system when variable data is to be printed directly onto foil without first having to print a label. Flexicode is a budget-oriented entry-level system focused on important and basic functions. Flexicode works with digital thermal transfer technology. This method stands for exceptionally good print quality and maximum reliability. Flexicode‘s easy maintenance, supported by a multitude of diagnostic functions, is an additional advantage.

Locust high resolution thermal ink jet printer

Compact sleek design to fit easily on to any production Line.

simple cartridge printhead system.

All bracketry included with Printer.

Ideal for carton taper and flatbed conveyor applications

Simple message selection, hold up to 30 Messages

Message transfer via USB thumb drive

Sensors detect product speed and direction. Changing ink is simple and clean

Speed, Pre-dispensing and Product Delay together with a manual dispense button for ease of use, via the front panel, as well as Status signal indicator for: Start, Stop, Disable, Feed, Power-On and Error. Other options include: low label alarm, label count, output connection to other systems ( e.g. conveyor line stop when error signaled).The clutch less stepper motor drive delivers infinitely variable Labeling speed with precision positioning.

ConTecH are leaders in supplying the Food Industry with highly successful turnkey project solutions. ConTecH custom design and manufacture a wide range of conveyor systems and conveyor equipment using the latest technology and design techniques. We provide guaranteed solutions to improve your operating systems by improving efficiency, reducing costs and downtime, simplifying your methods and increasing output.

DJ1 thermal ink jet printer,

Prints up to 4 lines

Porous and non-porous inks

Compact industrial design

Changing ink cartridge is clean and simple

Horizontal and vertical printing capabilities

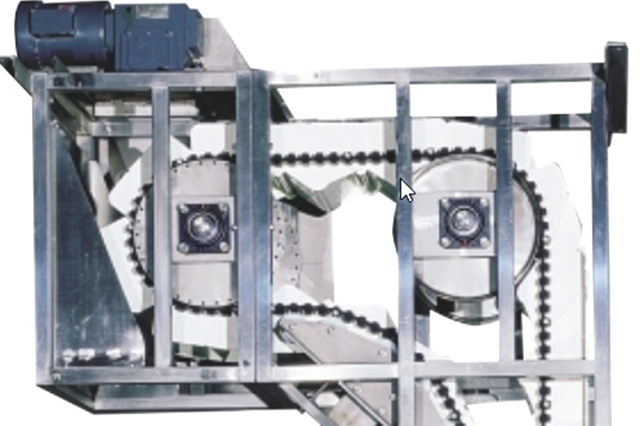

FlexMove wedge conveyors are used to convey products from production floor level to another level higher or viseversa using FlexMove wedge top chain. It uses two conveyors facing each other to provide fast and gentle vertical and/or horizontal transport of products. Its proven function provides a continuous high capacity operation, never requires the product to be stopped and ensures product separation. FlexMove wedge conveyors are also used in rinsing application where products need to turn up side down for rinsing process. There are many configurations of wedge conveyors such as “C”, “S”, “U” or “n

The heart of the TipTrak design is the patented TipTrak chain. This is elastomer molded around and bonded to a core of multiple strands of stainless steel aircraft cable. Similar to a timing belt in design, it has positive drive. With the stainless steel cable core (which is pre-stressed at the time of molding to eliminate elongation), the TipTrak drive belt combines all the advantages of a chain, strength and positive drive, with the benefits of a belt: no moving parts, corrosion resistance and long life. This unique design eliminates the need for sprockets except at the drive end. At all other points the chain runs in a flanged pulley much like a V-belt in a sheave.

The CF-25 is the latest in a series of industrial grade, high performance case erectors from Little David®. This case erector is designed to form and bottom-seal corrugated boxes at speeds up to 15 cases per minute. The Little David® CF-25 is an automatic system that erects and bottom seals corrugated cases at speeds from 10 to 15 cases per minute. The CF-25 case erecting solution is ideal for applications that require more throughput than manual case erecting can provide. This versatile system creates instant labor savings and increases production for a wide range of medium-speed applications.

© Allure-Pac. All Rights Reserved | Designed and Hosted by Newtrendz Australia Pty Ltd